I just found a Velosolex 4600 V3 in Black, a color I do not have so I will rebuild this guy over the 2021 Winter period, will keep me a little more busy than I already am !

A Yellow Velosolex 4600 V3 Engine Rebuild

Thursday, December 3, 2020

Sunday, October 18, 2015

First turns

The engine is fully back together now, the ultimate question is, did I do a good job? Will it run? will it run well? Well the proof is in the pudding, so here is the video of the first attempt at starting the engine

Next I will need to break the engine in some more and finally add the rest of the items that go on there, the top cover with the air filter and air filter cover, the engine cover and the fly wheel cover, and it will be time to get the bike back together

Next I will need to break the engine in some more and finally add the rest of the items that go on there, the top cover with the air filter and air filter cover, the engine cover and the fly wheel cover, and it will be time to get the bike back together

Friday, October 16, 2015

finishing the reassembly - and forgetting to take pictures

Today the rest of the motor went back on, the 6202 bearing and the coil/stator plate, and finally the rotor, on the other side the carb got taken apart and cleaned thoroughly. The tank was broken so I used a second hand I had on the shelf

Finally the fuel lines were cleaned, the line between the tank and the pump was stuck, so I had to burn out the solid gunk and oil in it and blow the line with compressed air..

Finally the fuel lines were cleaned, the line between the tank and the pump was stuck, so I had to burn out the solid gunk and oil in it and blow the line with compressed air..

Top end of the engine

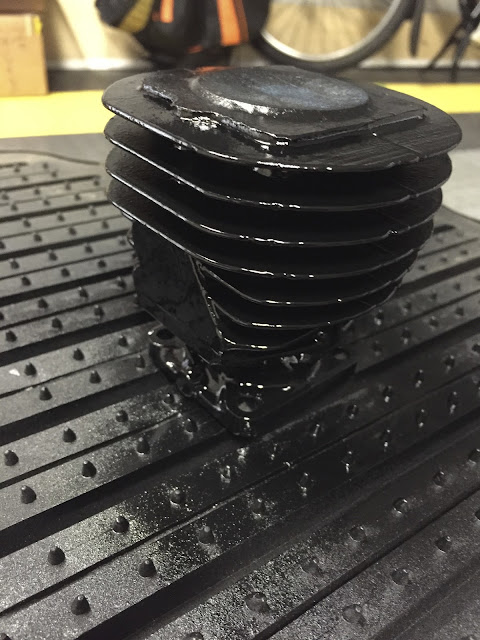

After honing the cylinder and repainting with high temp black paint to give it a new lease on life, it's time to put this back on the engine

Crank case gasket in place and leveled to make sure we have a level seat for the cylinder and cylinder gasket, the protruding tool on the front of the engine blocks the crank shaft when assembling the engine and prevents parts from moving excessively

Here it is with the rest of the top of then engine and.. a spark plug!

First the piston on the crank shaft, then a brand new gasket for the case, making sure it is level with the case. A base gasket for the cylinder, the cylinder itself, a top head gasket, the newly bead blasted head, a brand new Champion L86 spark plug and off we go

After cleaning the head, the decompressor assembly was also cleaned and the seat of the decompressor was put back in shape with the original Solex seat miller tool

Crank case gasket in place and leveled to make sure we have a level seat for the cylinder and cylinder gasket, the protruding tool on the front of the engine blocks the crank shaft when assembling the engine and prevents parts from moving excessively

Here it is with the rest of the top of then engine and.. a spark plug!

Thursday, October 15, 2015

Piston, Cylinder and Clutch!

Next step will be to add the clutch, a very small amount of grease on the crank shaft, just enough to lubricate the inside bushing of the roller:

Then comes in order, a thin washer and a nut that will be tightened, a beveled washer with a seal in it and the spring loaded clutch. Finally the nut that will need to be tightened as hard as possible to make sure the clutch does not slip. The most important here is to keep the side with a '+' sign facing outside so the clutch engages properly

Done!

Then comes in order, a thin washer and a nut that will be tightened, a beveled washer with a seal in it and the spring loaded clutch. Finally the nut that will need to be tightened as hard as possible to make sure the clutch does not slip. The most important here is to keep the side with a '+' sign facing outside so the clutch engages properly

Done!

Tuesday, October 13, 2015

Changing the main bearing

After tearing the engine down and bead-blasting with glass beads, it's time to try to put it back together. the trick is to first clean all the screw location and air vents in the main engine block, then degrease the location of the bearing before doing anything. Here are all the parts before reassembling: crank case, the thin shim that goes in bearing well, a new 6203 RS (sealed) bearing, the crank shaft and the seal that goes on the other side. You will also need some bearing sealant or glue to make sure it won't move

Once you have all the parts ready, you will need to heat the crank case around the bearing location, you can heat it up in an oven, I use a blow torch, making sure to stay far away from the case as aluminum will melt if overheated. This is just so that the metal expands and pushing both the shim and the bearing is easier

To make sure it goes straight, I start with the bearing and a mallet, then insert the crankshaft and use my hydraulic press to push it down in position all the way.

Last bit to do, while the case is still warm, push back the aluminum lip with a small hammer to fold over the bearing and seal it, make sure if you attempt this to do it slowly and softly not to break the aluminum of the case

That's it, it's in place, I will now leave it alone to allow for the bearing compound/glue to polymerize and harden, then the rest of the engine will be added..

Once you have all the parts ready, you will need to heat the crank case around the bearing location, you can heat it up in an oven, I use a blow torch, making sure to stay far away from the case as aluminum will melt if overheated. This is just so that the metal expands and pushing both the shim and the bearing is easier

To make sure it goes straight, I start with the bearing and a mallet, then insert the crankshaft and use my hydraulic press to push it down in position all the way.

Last bit to do, while the case is still warm, push back the aluminum lip with a small hammer to fold over the bearing and seal it, make sure if you attempt this to do it slowly and softly not to break the aluminum of the case

That's it, it's in place, I will now leave it alone to allow for the bearing compound/glue to polymerize and harden, then the rest of the engine will be added..

Saturday, October 3, 2015

Cylinder overhaul

The cylinder having rust inside and out, it got masked to protect the inside of the cylinder and transfers, then bead blasted, and painted with high temp enamel.

the inside of the cylinder got deglazed with very fine sandpaper dipped in oil and gas mix over a piece of PVC to make sure the cylinder does not get ovalized..

the inside of the cylinder got deglazed with very fine sandpaper dipped in oil and gas mix over a piece of PVC to make sure the cylinder does not get ovalized..

Subscribe to:

Comments (Atom)